Fill has been building wood processing machines for more than 50 years and has been involved in bandsaw technology for some 15 years now. Meanwhile, the 200th SPEEDLINER 920-350 HYBRID bandsaw module has been delivered to a customer, where 14 saw heads were installed all at once as part of a major project. Influenced by the quality requirements of the automotive industry, Fill SPEEDLINER bandsaws have become the state of the art in industrial board production. The fact that a company which influences the high standards of the international automotive industry also manufactures production systems for the wood processing industry is both a rarity and a fortunate outlier. Fill frequently acts as a general contractor on major projects involving the fully-automated production of millions of square meters of three-layer boards per year. The majority of these enormous systems, such as bandsaw lines, sorting systems, joint gluing systems, spot repair systems, and logistics equipment, are manufactured by Fill itself.

Gurten, November 9, 2022 – Fill has been developing and building high-precision fine-cutting bandsaws for the production of lamellae since 2007. 150 million square meters of wood are cut worldwide on Fill bandsaws every year. In Europe, all the prominent board producers manufacture their products on systems from the Upper Austrian machine engineering company. „When it comes to industrial cutting of sawn timber into lamellae for the production of multilayer boards and parquet, our high-performance fine-cutting bandsaws of the SPEEDLINER product family have become the industry standard worldwide. We have brought together precise fine-cutting and high performance under one roof,“ explains Erwin Altendorfer, Head of the Wood Competence Center at Fill.

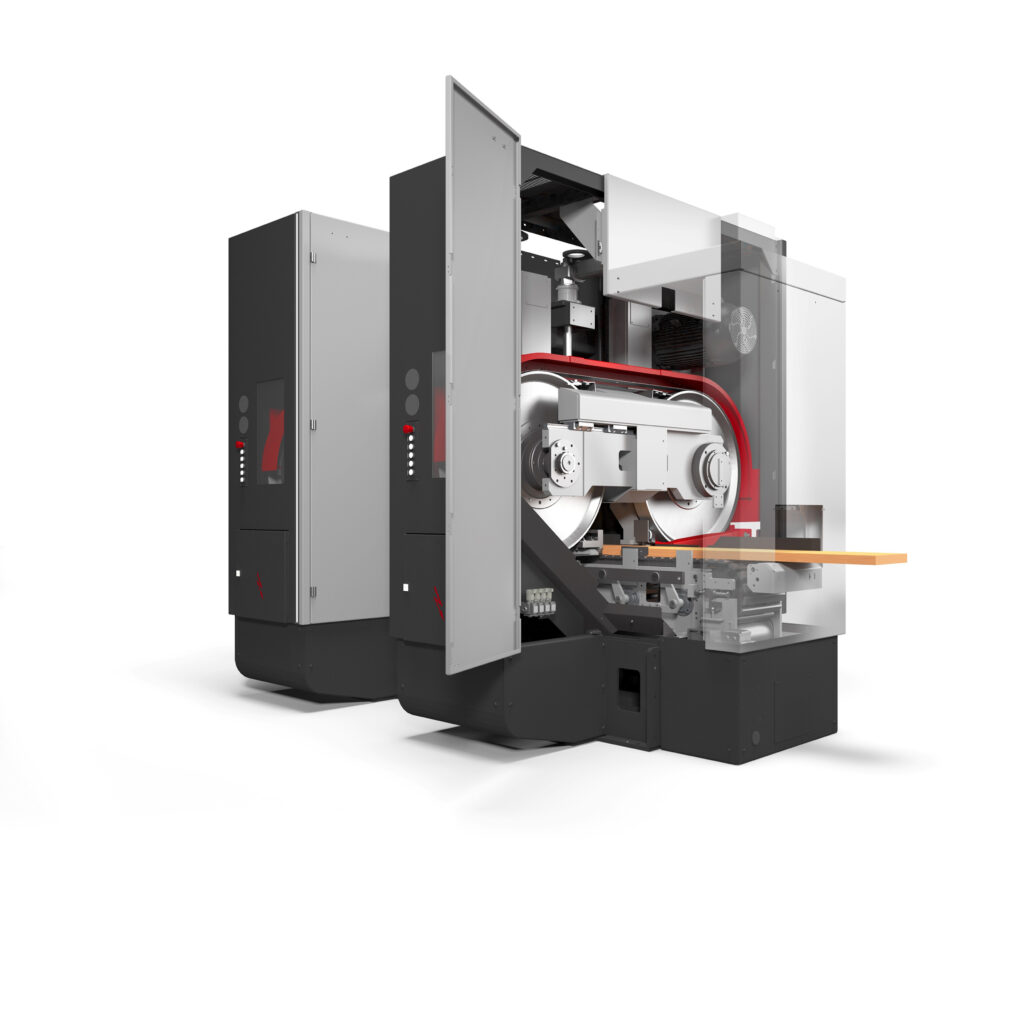

Precise and productive

The SPEEDLINER bandsaws combine maximum precision with performance and flexibility. Their sturdy construction and use of high-quality components allow multilayer operation in consistently high quality for many years to come. Depending on the raw material, the high-performance bandsaws can be operated with feed rates of up to 40 meters per minute. The extremely narrow kerf of as little as 1.1 millimeters enables substantial material savings and ensures highest levels of efficiency and cost-effectiveness. This is supplemented at Fill by the extensive project management expertise acquired from years of experience with major projects. Depending on individual requirements, Fill SPEEDLINER HYBRID bandsaws can be operated as freestanding machines or as multi-head systems with several in-series, automated modules. With new methods for processing and preparing wood, the Upper Austrian machine engineering experts are creating innovative and sustainable solutions in timber construction.

Corporate data

Fill is a leading international machine engineering company based in Gurten, Upper Austria. With sophisticated high-tech systems and custom manufacturing solutions for metal, plastics and wood, Fill makes its customers the best in their fields. The automotive, aviation, sports and building industries all benefit from Fill’s expertise. Since it was founded in 1966, the company has distinguished itself through enormous innovative strength, strong values and the best jobs. “If you are seeking the best solution, shape your future with Fill” is the guiding principle of the company’s more than 950 employees. “Wir sind 1! We are one!” is their vision and stands for togetherness not only with the team, but also with customers, suppliers and partners. The company is 100 percent family-owned and managed by Andreas Fill (CEO), Martin Reiter (CSO), Alois Wiesinger (CTO), and Günter Redhammer (COO). In 2021, Fill recorded sales of around 180 million euros.

Further information can be found at: www.fill.co.at