As the main partner on the LOWFLIP (‘Low Cost Flexible Integrated Composite Process’) project, Fill was presented with the JEC Award on September 22, 2016 at the Experience Composites trade fair in Augsburg. The Upper Austrian high-tech company received the award together with the Stuttgart-based Institute of Aircraft Design (IFB). LOWFLIP is a cost-efficient, flexible and automated process for producing GFRP and CFC components.

Augsburg/Gurten, October 24, 2016 – Systems concepts were developed and preliminary tests conducted in collaboration with research partners from Spain, Germany, the Czech Republic, and Austria. Fill subsequently built a prototype system, for which initial tests have been successfully conducted. “We are particularly pleased to have already received specific inquiries from potential customers for this project,” said Wilhelm Rupertsberger, Manager of the Plastics Competence Center at Fill.

Project completion in Gurten

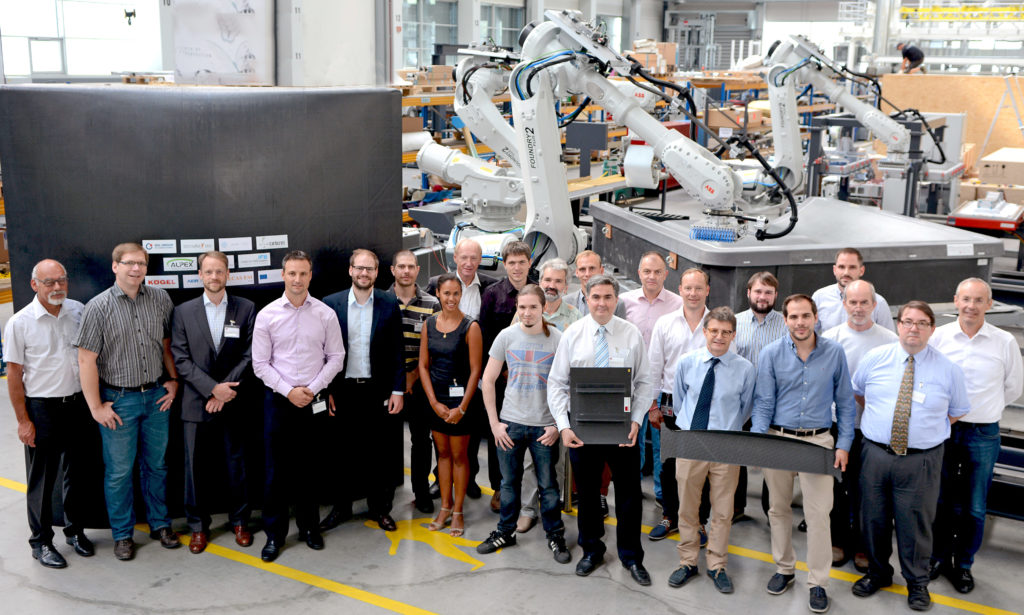

The final meeting for the EU-funded LOWFLIP project was held at Fill Machine Engineering in Gurten at the end of September. The requested demo components (truck trailer front panel, strut brace and end segment of aircraft tail cone) were also produced. The experts in attendance (including from Airbus) were impressed by the results. Dates for further implementation plans were agreed at the meeting. One of the two systems built by Fill will be presented at the Fill exhibition booth during the K trade fair in Düsseldorf (October 19-26, 2016); the other one will be set up in Stuttgart at the Institute of Aircraft Design.

Team spirit

In his statement, Wilhelm Rupertsberger thanked all employees who were involved in the project for their hard work. There was a special mention for Harald Sehrschön, who managed the project successfully, Michael Schneiderbauer for the sophisticated technical solutions, Gerhard Sieglhuber for the perfect production of the demo components, and Christian Rosner, who became a robotics expert within just a few weeks and programmed the complex system perfectly.

Corporate data

Fill is a leading international machine and plant manufacturing company serving diverse branches of industry. The family-owned business excels in the use of the latest technology and methods in management, communication, and production. Business operations encompass the fields of metal, plastics and wood for the automotive, aircraft, wind energy, sport and building industries. The company is the global market and innovation leader in aluminum core removal technology, casting technology, wood bandsaw technology, as well as in ski and snowboard production machines. Andreas Fill and Wolfgang Rathner are joint CEOs of the company founded in 1966 that is still completely family-owned and now has more than 700 employees. Fill is expecting to generate sales of approximately EUR 130 million in 2016.

Further information can be found at: www.fill.co.at

Allgemein

JEC Award for LOWFLIP project goes to Upper Austria

Fill Machine Engineering has won an award for an innovative composite project conducted in collaboration with a European consortium.

24

Okt

Okt