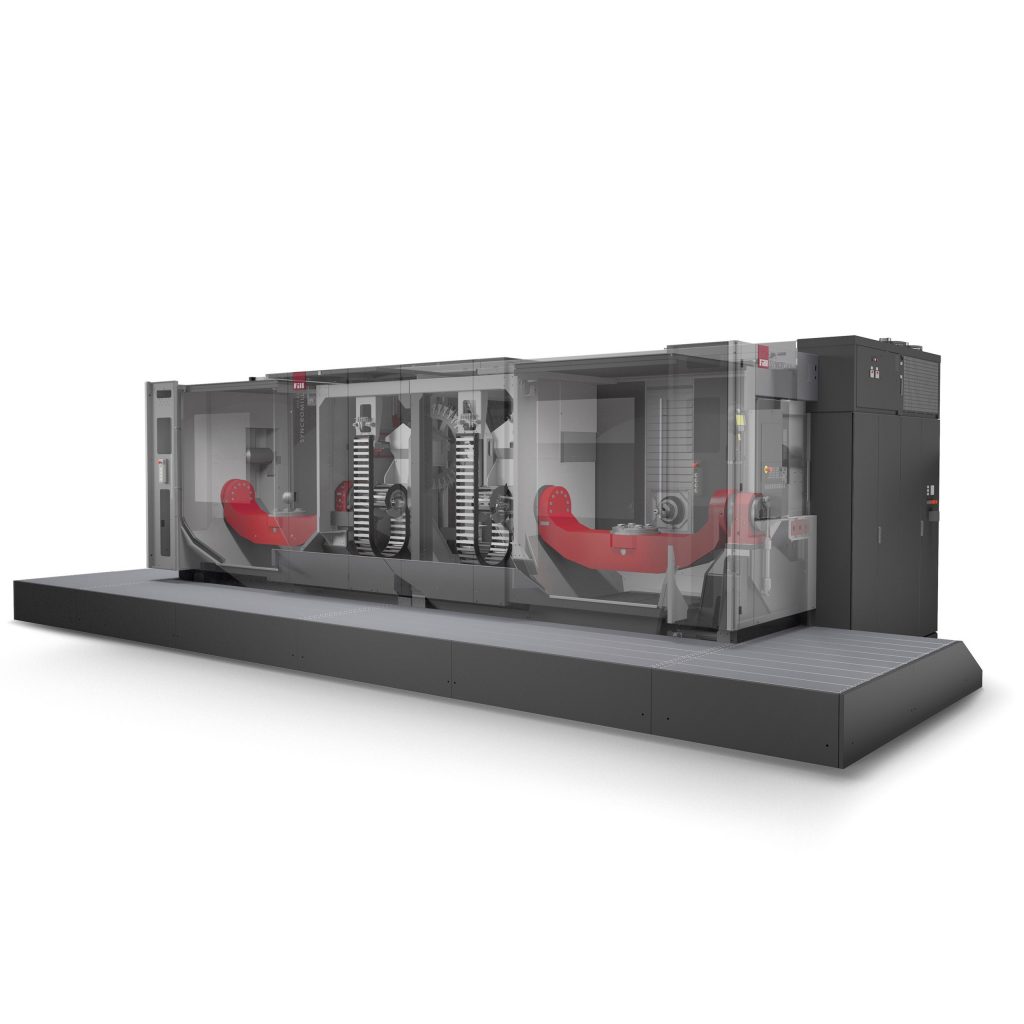

With their most recent development, the machine engineering experts from Fill have reached an important milestone for future vehicle architectures. The two latest generations SYNCROMILL D11 (single machine) and SYNCROMILL D22 (dual machine) represent the best solution for applications involving high-precision machining of large-volume components, such as side members, front and rear axle carriers, chassis components, structural vehicle parts, and battery trays. Optimizations in the area of chip-to-chip time, an enlarged machining space, and sensational acceleration values result in a huge reduction in component costs, to name but a few of the many improvements that have been implemented in the course of further development. Furthermore, Fill has achieved comprehensive digitalization in metalworking in the sense of Industry 4.0, allowing machines and systems to be utilized even more efficiently.

Gurten, 28 September 2020 – „The symbiosis of virtual and real processes – i.e., digital twin – opens up completely new perspectives in terms of planning, material utilization, productivity, and system intelligence. The entire production process is elevated to a higher level, both in terms of quality and cost-effectiveness,“ explains Friedrich Dallinger, Head of the Metal Machining Technology Competence Center at Fill.

Significant reduction in machining costs

The new generation of SYNCROMILL D machining centers impresses with a range of optimizations. For example, it has been possible to reduce chip-to-chip time from 4.5 to 3.6 seconds. The machining area of the machine has been enlarged by ten percent within the same external dimensions. The increase in machine stiffness and optimization of feed, speed, and acceleration parameters will significantly reduce the machining times even further. Thanks to the numerous modifications, component machining costs can be reduced by an average of 20 percent.

Modular construction

The modular construction of the SYNCROMILL D allows all versions to be configured on a uniform basic design. For example, tool interfaces are available in HSK-63, HSK-80, and HSK-100, thereby covering the entire component spectrum perfectly. In order to react as quickly as possible to changing requirements in production, provision has been made for both manual loading of the machine by the operator and automated loading by linear portal or robot. In addition, the ideal arrangement and design of the installed components ensures optimum accessibility for servicing and maintenance tasks. This reduces potential downtime many times over. As a competent systems partner, Fill offers the option to integrate new technologies, such as friction stir welding (FSW) or the installation of wire thread inserts, directly in the machining center.

We may live in a virtual age, but the innovations at Fill are very real. The latest machine developments can be viewed in the Fill Future Zone, a 4,500 m² high-tech center for digitalization opened in 2020 at the Gurten plant. On request, test runs are also conducted with customer parts. Interested parties can visit the Fill Future Zone by appointment and see Fill’s extensive expertise for themselves.

Corporate data

Fill is a leading international machine and plant manufacturing company serving diverse branches of industry. The family-owned business excels in the use of the latest technology and methods in management, communication, and production. Business operations encompass the fields of metal, plastics and wood for the automotive, aircraft, wind energy, sport and building industries. The company is the global market and innovation leader in aluminum core removal technology, casting technology, wood bandsaw technology, as well as in ski and snowboard production machines. Andreas Fill (CEO), Alois Wiesinger (CTO), and Günter Redhammer (COO) are the managing directors of the company founded in 1966, which is still completely family-owned and now has about 920 employees. In 2019 the company recorded sales of around 169 million euros.

Further information can be found at: www.fill.co.at