“Cost-efficiency through automation” is the name of the game with the systems from Fill Machine Engineering. New production concepts for intelligent lightweight construction were presented at the K trade fair from 19 to 26 October 2016 in Düsseldorf. The process-optimized and automated procedures reduce costs and increase productivity. With this, the Austrian special machine builder is driving development forwards in the modern plastics industry.

Düsseldorf/Gurten, 08 November 2016 – New polyurethane processing methods. Load-oriented insertion of thermoplastic tapes. Vaporless processing of particle foams – Fill Machine Engineering caused a stir at the K trade fair in Düsseldorf with numerous innovations.

Qualified interchange between research and industry

“Our extremely innovative and productive Development department deals constantly with future-oriented technologies. In combination with our longstanding experience in the field of plastics production, this is the driving force behind new developments,” explains Wilhelm Rupertsberger, Manager of the Fill Plastics Competence Center. The result is innovations such as the load-oriented insertion of fibers into CFRP components for material-efficient design, as presented in Düsseldorf. This procedure is integrated into automated production processes. This in turn has resulted in such developments as a new high-performance laying system for processing thermoplastic tapes, which allows innovative products to be manufactured. Preforms are produced in the injection-molding frequency with this process. The presented prototype system and performance simulation were one of the highlights at K 2016.

High-performance laying system for thermoplastic tapes

In the composites sector, load-oriented insertion of fibers into the component forms the basis for its material-efficient design. Fill’s primary focus lies in textile-handling processes, such as cutting, laying, joining, forming, and braiding. This applies just as much to the processing of dry fibers as it does to prepreg processes and thermoplastic tapes. With a newly developed, high-performance laying system for processing thermoplastic tapes, Fill offers various possibilities for producing innovative, high-volume composite products – particularly for the automotive industry.

Meeting point for the industry

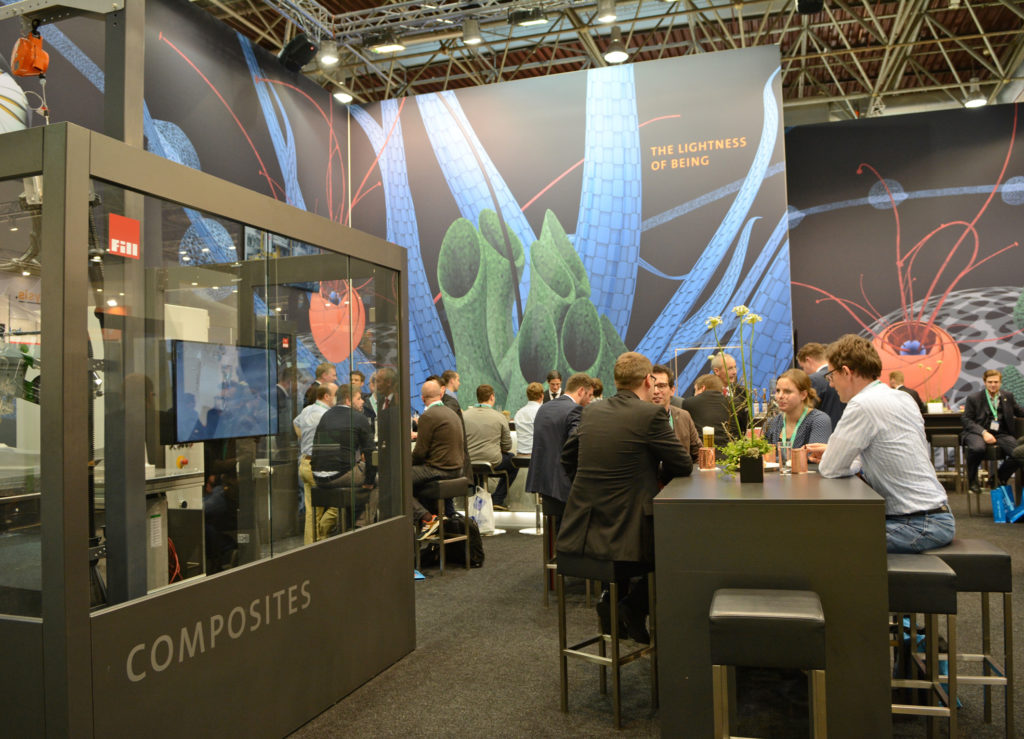

The Fill exhibition stand was a very popular platform for knowledge transfer at the international showcase exhibition of the plastics industry, K 2016, from 19 to 26 October in Düsseldorf. Customers, partners, and friends of the company met up to exchange information and network over a refreshing cocktail in a relaxed atmosphere, whereby the Upper Austrian machine engineering experts were pleased to receive several concrete order inquiries.

Corporate data

Fill is a leading international machine and plant manufacturing company serving diverse branches of industry. The family-owned business excels in the use of the latest technology and methods in management, communication, and production. Business operations encompass the fields of metal, plastics and wood for the automotive, aircraft, wind energy, sport and building industries. The company is the global market and innovation leader in aluminum core removal technology, casting technology, wood bandsaw technology, as well as in ski and snowboard production machines. Andreas Fill and Wolfgang Rathner are joint CEOs of the company founded in 1966 that is still completely family-owned and now has more than 700 employees. Fill is expecting to generate sales of approximately EUR 130 million in 2016.

Further information can be found at: www.fill.co.at

Allgemein

Mechatronics from Upper Austria provides new impetus in the plastics industry

Fill Machine Engineering presents high-precision, efficient manufacturing processes at the K 2016 trade fair in Düsseldorf.

08

Nov

Nov