The new SWARCO Advanced Industry Systems business segment caters to the building materials industry’s need for glass filler beads. SWARCOFORCE glass filler beads are made from soda-lime glass cullet. Used as filling agents, they enhance product functionality by impacting properties, such as rigidity and pressure resistance, warping and shrinking behaviour, fluidity, colour and surface gloss.

Amstetten, 18th June 2020 – Processing and refining flat glass cullet into micro glass beads is SWARCO’s core competence. With over five decades of experience and continuous research and development activities at the Competence Center for Glass Technology in Amstetten, Austria, the company has always been the front runner, setting new standards in the glass bead industry. With the new SWARCO Advanced Industry Systems business segment, decades of research and know-how on the universal applications of micro glass beads are now made accessible to industry.

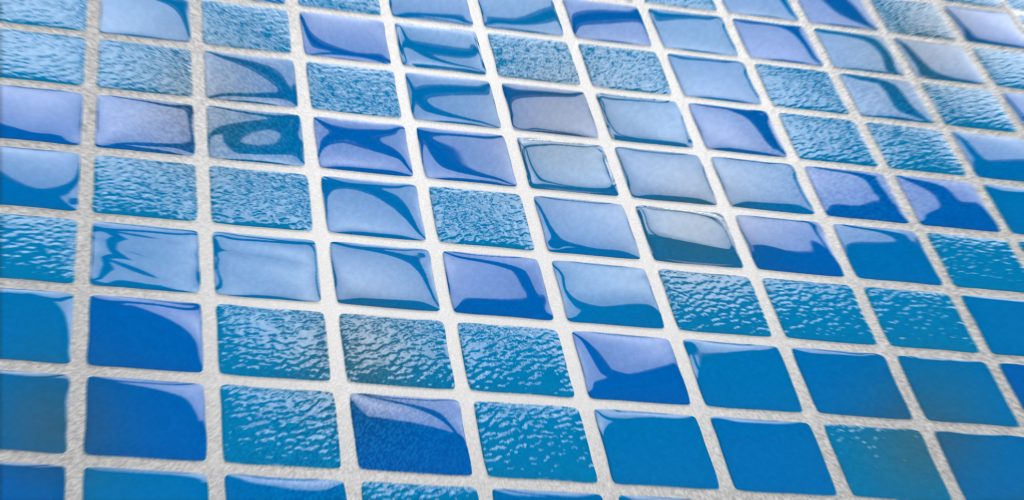

Translucent Joint Sealants

In the building materials industry, glass filler beads by SWARCO Advanced Industry Systems are used, among others, in translucent joint sealants, which break light in addition to reflecting it. This enhances the colours of glass mosaics and glass tiles and gives them a shimmering effect. Surface structures compacted with SWARCOFORCE glass filler beads are waterproof and easy to clean.

Used as additives to floor sealants, micro glass beads help improve skid resistance. Coated with adhesion promoters, they achieve better adhesion with the matrix material.

The First Choice for Filling Agents

The vision “SWARCOFORCE – your first choice for industrial glass beads as filling agents” is now within reach. Leading building materials manufacturers in Europe and Asia are already among SWARCO Advanced Industry Systems’ clients.

“We offer a wide variety of glass beads and grain sizes. Our production process ensures narrow tolerance ranges and allows for particle-size distributions tailored to clients’ needs,” says Robert Buchinger, in charge of Business Development at SWARCO Advanced Industry Systems.

Circular Economy

SWARCO Advanced Industry Systems has the necessary know-how to produce high-grade glass beads from recycled products. Also, the origin and trajectory of the glass can be traced. To avoid transporting the raw materials over large distances, they are purchased in the region near the different production facilities.

About SWARCO Advanced Industry Systems

As part of the international SWARCO group, SWARCO Advanced Industry Systems leverages the universal benefits of glass beads for special industry applications. In 1969 SWARCO started out with the manufacture of tiny reflective glass beads for road markings. Today, the group has grown into one of the world’s leading manufacturers of micro glass beads, with production facilities in Europe, the United States and Saudi Arabia. Micro glass beads serve as high-grade filling agents for industrial applications and as blasting media for surface treatment applications. In traffic technology, micro glass beads which are embedded in the marking materials reflect the beam from the headlight back to the driver, making road markings visible; this enhances road safety, especially at night.

For further information visit www.swarco.com/ais