Fill presented smart automation solutions for the whole foundry process at the leading trade fair Euroguss 2018 in Nuremberg from 16 to 18 January 2018. The intelligent interconnection of processes and automated production equipment result in a robust, highly efficient production system. All production stages are covered in the fields of light alloy and steel casting. From casting, cooling, and decoring to premachining, testing, and finishing. Perfect coordination allows synergies to be exploited and high-quality castings to be produced economically.

Nuremberg/Gurten, 25 January 2018 – Downsizing, weight and exhaust gas reduction, CO2 emissions – these are the major issues in modern casting technology. "We optimize the processes and develop new technologies that deliver convincing results and ensure the highest levels of cost-effectiveness and process stability in the harsh foundry environment," explains Thomas Rathner, Head of the Fill Casting Technology Competence Center.

Low pressure caster b

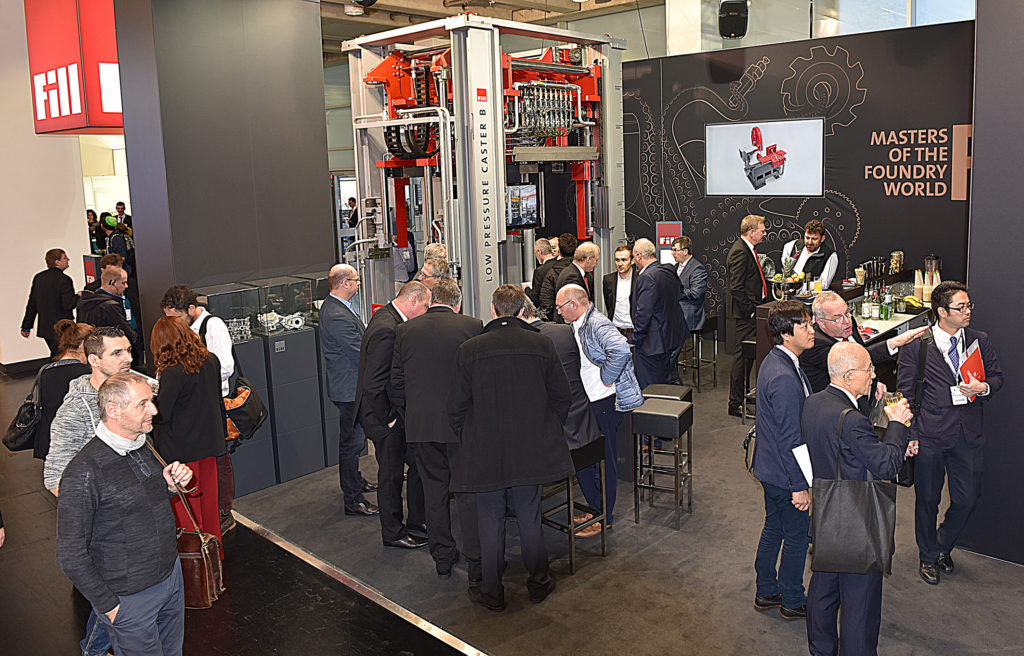

The low pressure caster b low-pressure casting machine was presented on Fill’s exhibition stand at the Euroguss in Nuremberg from 16 to 18 January. It can also be used as a basic machine for back-pressure die-casting. This innovation is characterized by a larger clamping surface and a longer stroke in a small design. Further benefits include simple handling and ergonomic, service-friendly maintenance. Together with a fully automated shuttle system for changing furnaces and tools, the technology further refined by Fill yields a highly efficient production system.

Digital products

Another highlight was the presentation of the digitalization driven by Fill’s expert team. One remarkable step towards Industry 4.0 is the complete networking of machines with the machine workflow software platform and visualization of the product and production data with the newly developed app for iOS and Android operating systems.

Dialog connects

Fill exhibition stand 123 in Hall 7A was very busy on all three days of the trade fair. Fill Foundry World innovations were presented and the entire value chain of the foundry industry discussed in a relaxed atmosphere. Many international customers, partners, and friends of the company took advantage of the opportunity to meet Fill’s experts and discuss the latest developments and innovative systems directly with them.

Corporate data

Fill is a leading international machine and plant manufacturing company serving diverse branches of industry. The family-owned business excels in the use of the latest technology and methods in management, communication, and production.

Business operations encompass the fields of metal, plastics and wood for the automotive, aircraft, wind energy, sport and building industries. The company is the global market and innovation leader in aluminum core removal technology, casting technology, wood bandsaw technology, as well as in ski and snowboard production machines. Andreas Fill and Wolfgang Rathner are joint CEOs of the company founded in 1966, which is still completely family-owned and now has about 800 employees. In 2017, the company recorded sales of around 160 million euros.

Further information can be found at: www.fill.co.at

Allgemein

A look into the future of casting technology

The Upper Austrian machine engineering experts herald a new era with the Fill Foundry World: Presentation at Euroguss 2018

25

Jan.

Jan.