The tranquil town of Gurten in the Upper Austrian Innviertel region is not exactly renowned as a hot spot for winter sports. Yet this is where the machines and systems that make the world’s most modern skis and boards come from. Last year, the largest ski project in the company’s history was completed, thereby reinforcing Fill’s position as the global market leader in ski production machines.

Gurten, February 14, 2022 – The success story began back in 1970 when Fill received an order for a grinding machine from Fischer Ski based in the neighboring town of Ried im Innkreis. This was the starting signal for successful cooperation and development which has lasted until today and made Fill the global market leader in ski and snowboard systems. Now all the major ski producers manufacture their sports equipment on machines from Fill.

Up there in the battle for Olympic medals

Above all, when the Austrian competitors win one medal after another in the alpine, Nordic, and snowboard disciplines – as they are doing currently at the Winter Olympics in Beijing – everyone involved at Fill is delighted. That’s because almost all the athletes use sports equipment that was produced on Fill machines and systems.

Largest ski project in company history

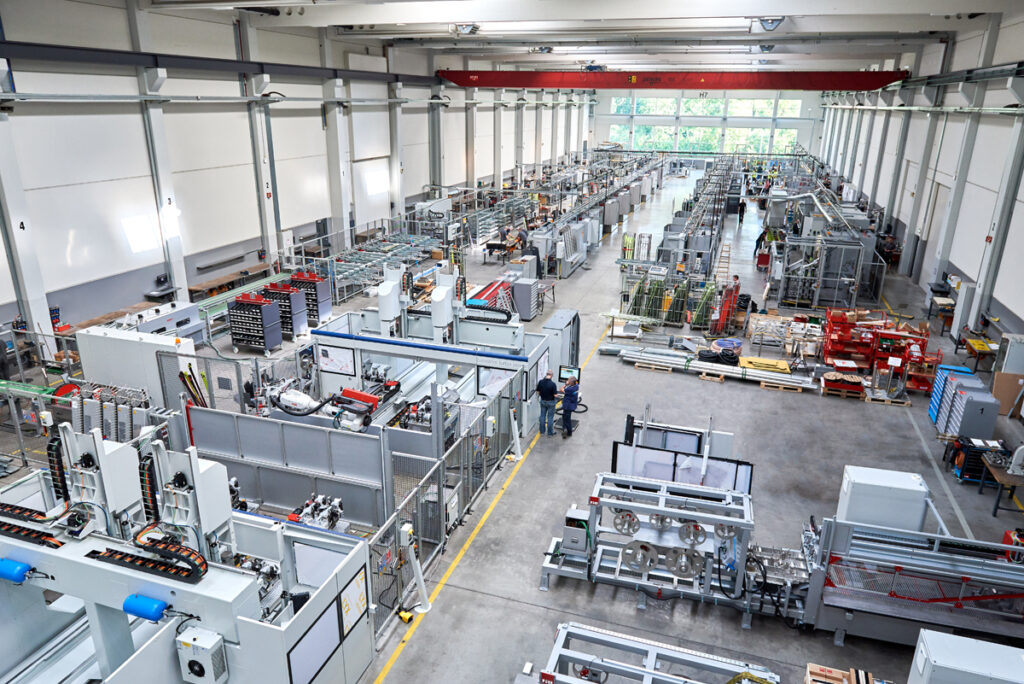

October 2020 marked another milestone in the collaboration between Fill and Fischer Sports. The contract covering multiple complete production lines for the Fischer plant in Mukachevo (Ukraine) was the company’s largest ever order in the field of ski machines. While the new production hall was under construction in Mukachevo until August 2021, five production lines for alpine skis and various subsections for cross-country ski production were built at Fill in Gurten. Starting at the end of August 2021, a total of 71 truck loads of ski production machines were transported to Mukachevo, some 900 kilometers away. Up to 35 fitters from Fill were on site at peak times during the installation operation. Installation and commissioning of the entire project is scheduled for completion by the end of the first quarter of 2022. Subsequently, Fill engineers will support the operating personnel with ramping up production at the Mukachevo plant. „The whole project is subject to great deadline pressure. Thanks to the enthusiasm and motivation of everyone involved – both at Fill and at Fischer – we will be able to keep to the ambitious schedule,“ reports Matthias Stiglbauer. Alongside his role as assembly team leader at Fill, the 28-year-old acts as a link between production and project managers and maintains a clear overview of this mega-project.

Corporate data

Fill is a leading international machine engineering company based in Gurten, Upper Austria. With sophisticated high-tech systems and custom manufacturing solutions for metal, plastics and wood, Fill makes its customers the best in their fields. The automotive, aviation, sports and building industries all benefit from Fill’s expertise. Since it was founded in 1966, the company has distinguished itself through enormous innovative strength, strong values and the best jobs. “If you are seeking the best solution, shape your future with Fill” is the guiding principle of the company’s more than 950 employees. “Wir sind 1! We are one!” is their vision and stands for togetherness not only with the team, but also with customers, suppliers and partners. The company is 100 percent family-owned and is managed by Andreas Fill (CEO), Martin Reiter (CSO), Alois Wiesinger (CTO) and Günter Redhammer (COO). In 2021, Fill recorded sales of around 180 million euros.

Further information can be found at: www.fill.co.at