The diverse application areas of SWARCOFORCE glass filler beads from SWARCO Indusferica make them an ideal filler material in plastics production. SWARCOFORCE glass filler beads impress with highest levels of precision and quality. SWARCO Indusferica will be presenting the special application areas and properties of the micro glass beads at the FAKUMA international trade fair for plastics processing in October.

Amstetten, September 27, 2023 – „SWARCOFORCE is the first choice for industry when it comes to filler materials made of glass beads. This is our vision. We work on this every day – on our product development as well as on the accuracy of fit for our customer requirements,“ explains Andreas Peham, Business Development. The innovative strength of SWARCO Indusferica has made its presence felt for decades now. The company is constantly setting new standards for glass beads.

Presentation of SWARCOFORCE at FAKUMA

SWARCO Indusferica will be presenting the special properties and application areas of SWARCOFORCE glass filler beads as an exhibitor at FAKUMA, the world’s leading trade event for industrial plastics processing. „We are looking forward to FAKUMA and the exchange of ideas and information with other international companies in the plastics technology sector,“ emphasizes Peham. SWARCOFORCE can be found at FAKUMA in hall B2 on stand number B2-2115 from October 17 to 21, 2023.

SWARCOFORCE glass filler beads are versatile

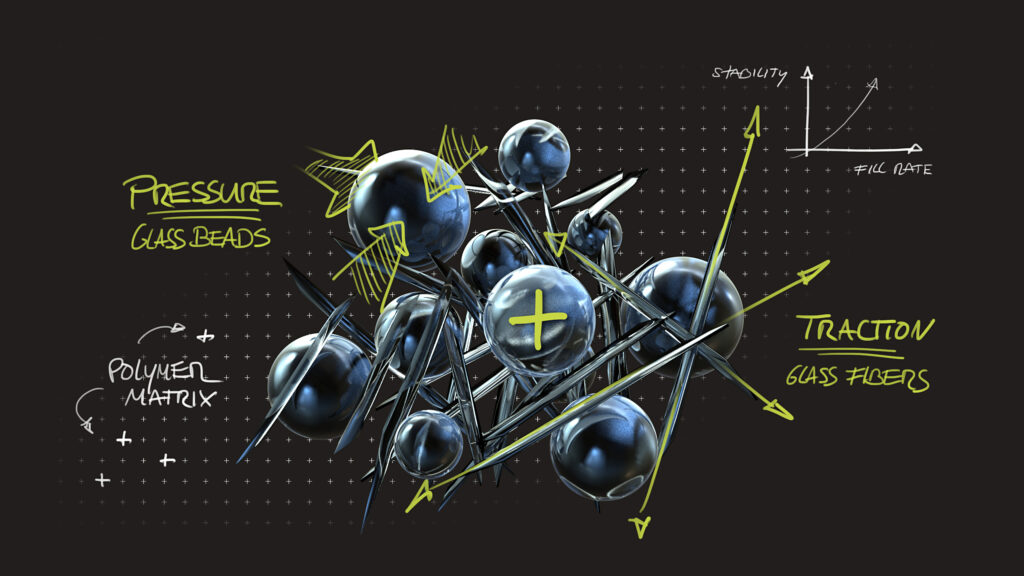

SWARCOFORCE glass filler beads have a significant effect on the properties of an end product. And their application areas are very diverse. Apart from paint finishes, colors, coatings, and building materials, SWARCOFORCE glass filler beads are used in the plastics industry. The micro glass beads are added to materials during compounding and processing of the plastic granulate, in order to improve the required characteristics. Thanks to their isotropy, SWARCOFORCE glass filler beads prevent warping and shrinkage in injection molding materials. Technical components, interiors and exteriors in the automotive sector, and 3D printing materials benefit from the improved product properties provided by SWARCOFORCE.

Glass filler beads in the sustainable circular economy

The glass filler beads are smelted from waste soda-lime glass cullets. Use of high-grade recycled glass saves SWARCO Indusferica 50 percent of the energy that would be required to manufacture sheet glass. The company has many years of experience and the necessary know-how to produce high-quality micro glass beads from recycling products. The origin of the glass is always traceable, and it is procured in the region around the production plants. In this way, SWARCO Indusferica avoids long transport routes and makes a significant contribution to sustainable production and environmental protection. Peham: „We as a company intend to push ahead intensively with the issues of circular economy and energy efficiency in particular.“

About SWARCO Indusferica

SWARCO Indusferica is part of the international SWARCO Group and utilizes the universal benefits of glass beads for special industrial applications. What began in 1969 as a business producing small reflective glass beads for road markings has evolved into one of the world’s leading manufacturers of micro glass beads, with production sites in Europe and the USA. Micro glass beads serve as a high-grade filler material in industrial applications and as a blasting abrasive for surface treatments. In the field of traffic technology, the micro glass beads embedded in the marking material reflect headlamp light to keep road markings visible. This increases road safety, particularly at night.

Further information at:

www.swarco.com/indusferica, www.swarco.com/join-grow