Economical, resource-conserving, and productive: With the high-performance multilayer laying system for thermoplastic tapes, the machine engineering experts from Fill have succeeded in developing a remarkable innovation. Tests and prototype production in the Fill Technical Center are in full swing and proceeding very promisingly. International companies are hugely interested in the new multilayer system. This was confirmed at the JEC international trade fair for composite materials in Paris from 6 to 8 March.

Paris/Gurten, 19 March 2018 – "The trend is increasingly towards thermoplastic composite components. So we are entering the market with our multilayer system precisely at the right time," reports Wilhelm Rupertsberger, Head of the Plastics Competence Center at Fill. The new high-performance laying system is currently undergoing its final phase of testing in the Fill Technical Center. It will be presented live to a trade audience for the first time in autumn 2018. The interest from potential customers is already huge. The first multilayer system has already been sold. In cooperation with Swinburne University in Australia, work is currently under way on an Industry 4.0 test lab. The Fill multilayer plays a central role in this project.

High level of automation expertise

With many years of experience in the plastics industry and concentrated systems automation expertise, Fill is a major driver of developments in this field. "Particularly in the aerospace sector, there is still plenty of potential for automated production processes to make manufacturing more efficient. We can score highly here with our experience from the automotive industry," says Wilhelm Rupertsberger. Fill supplies fully automated production sequences all along the process chain, from the fiber to the tested component.

Meeting point for the industry

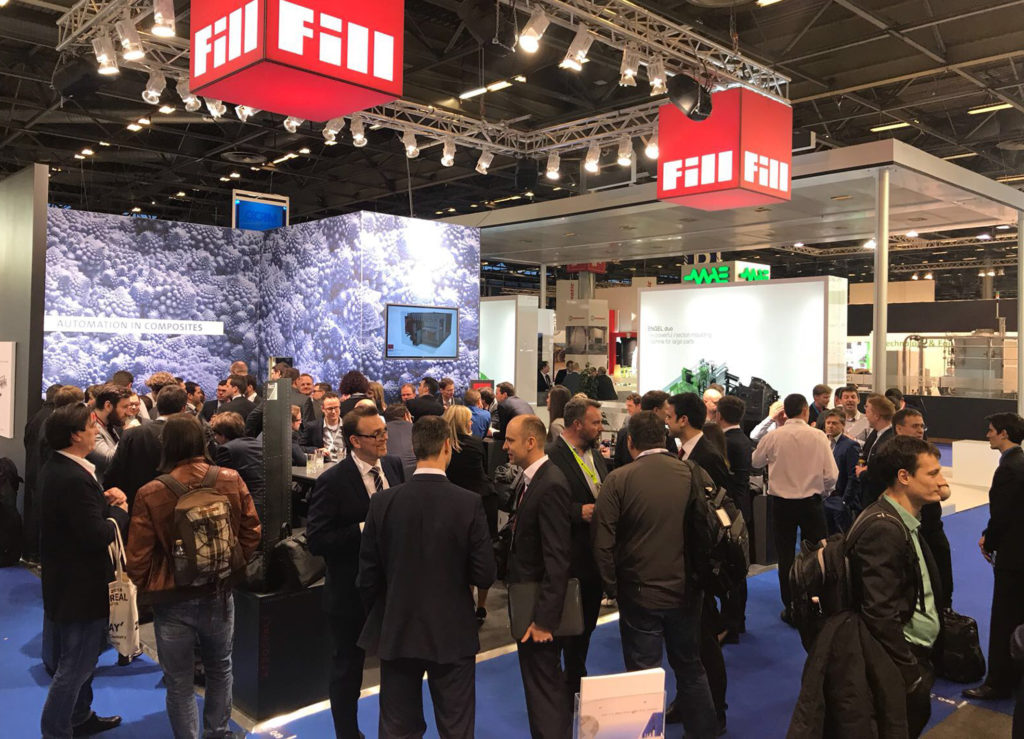

Fill’s exhibition stand at the JEC composites trade fair in Paris established itself as a very popular meeting place for the international trade visitors. The combination of first-hand technical information in a relaxed atmosphere and Austrian hospitality was much appreciated. "All the big players in the automotive and aerospace sectors were guests on our stand," says a very satisfied Wilhelm Rupertsberger about the large number of visitors.

Corporate data

Fill is a leading international machine and plant manufacturing company serving diverse branches of industry. The family-owned business excels in the use of the latest technology and methods in management, communication, and production.

Business operations encompass the fields of metal, plastics and wood for the automotive, aircraft, wind energy, sport and building industries. The company is the global market and innovation leader in aluminum core removal technology, casting technology, wood bandsaw technology, as well as in ski and snowboard production machines. Andreas Fill and Wolfgang Rathner are joint CEOs of the company founded in 1966, which is still completely family-owned and now has about 800 employees. In 2017, the company recorded sales of around 160 million euros.

Further information can be found at: www.fill.co.at

Allgemein

Digital leading-edge technology for lightweight composite construction

New multilayer system for thermoplastic tapes increases productivity, precision, and quality. Fill stand at JEC World in Paris a real visitor magnet.

19

März

März