In the plastics industry, micro glass beads play an important role as additives. SWARCOFORCE glass filler beads increase rigidity and pressure resistance, enhance surface quality and improve abrasion resistance. For injection moulding materials, glass filler beads reduce warping and shrinking, as well as sink marks, thanks to their isotropy. They are typically used in technical components, interior and exterior automotive parts, and 3D printed materials.

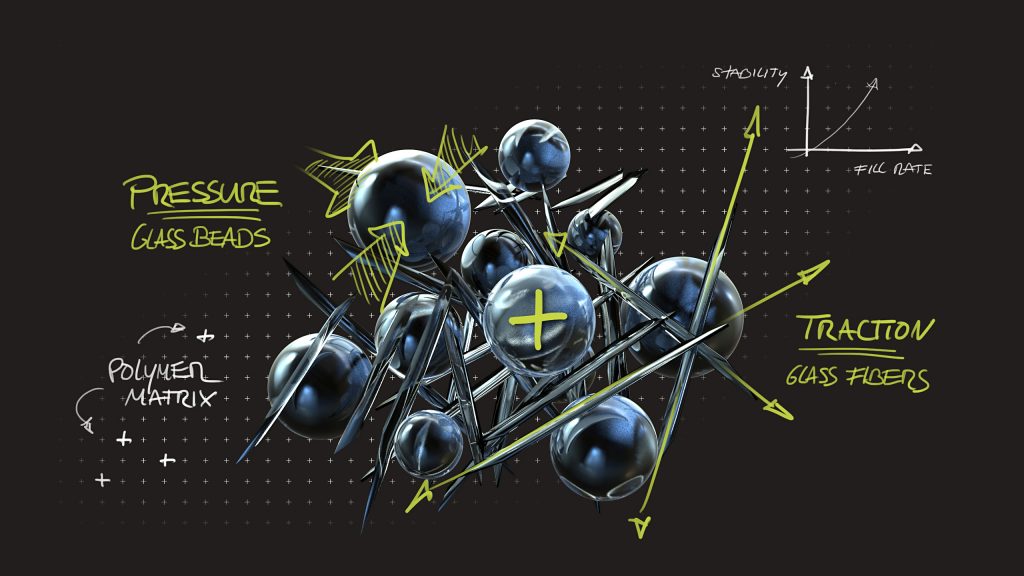

Amstetten, 8th September – Glass filler beads are important filling agents for plastics. In plastics engineering, SWARCOFORCE glass filler beads, which are made from soda-lime glass cullet, serve to optimize the properties of plastics, and are usually incorporated through compounding. The purpose of using glass beads to reinforce plastics is primarily to optimize and enhance their rigidity, reduce shrinking and improve their surface appearance. In hybrid combinations of glass-fibre and glass-bead reinforcements, the extra rigidity from the glass fibre comes together with the glass-bead reinforcement, which mitigates the plastic compound’s tendency to warp.

Post-Industrial Waste

The fact that SWARCOFORCE glass filler beads are able to meet expectations in this respect by using ecologically sustainable raw materials is a valuable and much appreciated asset, as it enables manufacturers to make green products, too. The raw materials used for SWARCOFORCE glass filler beads are subject to EU guidelines on chemicals and hazardous substances and comply with the REACH regulation and the RoHS directive. The recycled material used for production consists solely of cuttings and scraps from high-quality industrial glass. For an external verification of the quality and environmental focus of its work, SWARCO Advanced Industry Systems uses an ISO 9001 certified quality management system.

Particle-Size Distributions Tailored to Clients’ Needs

SWARCOFORCE glass filler beads can be made with a very wide variety of surface coatings, which defines the interaction between the glass and the matrix material used. SWARCO Advanced Industry Systems is your competent partner for tailor-made solutions using micro glass beads as filling agents in industrial applications. Many different grain sizes are available, and the production process ensures narrow tolerance ranges. Customized particle-size distributions are possible upon request.

About SWARCO Advanced Industry Systems

As part of the international SWARCO group, SWARCO Advanced Industry Systems leverages the universal benefits of glass beads for special industry applications. In 1969 SWARCO started out with the manufacture of tiny reflective glass beads for road markings. Today, the group has grown into one of the world’s leading manufacturers of micro glass beads, with production facilities in Europe, the United States and Saudi Arabia. Micro glass beads serve as high-grade filling agents for industrial applications and as blasting media for surface treatment applications. In traffic technology, micro glass beads which are embedded in the marking materials reflect the beam from the headlight back to the driver, making road markings visible; this enhances road safety, especially at night.

For further information visit www.swarco.com/ais